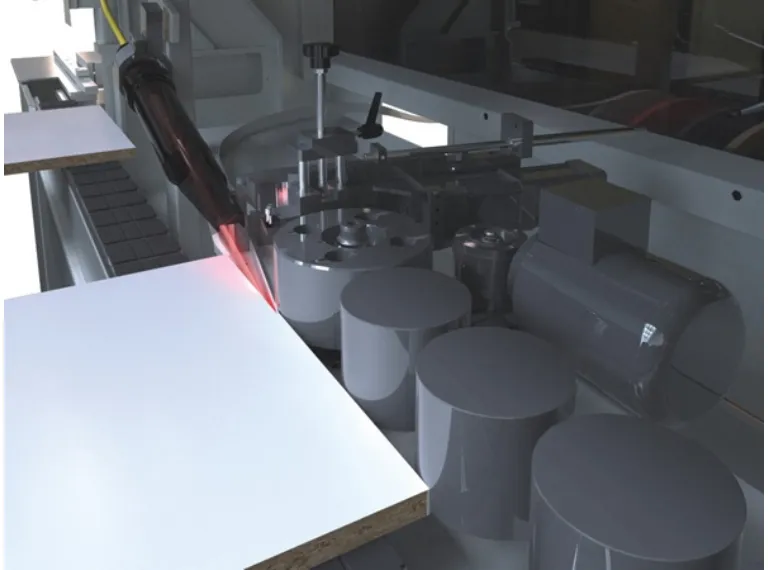

Laser technology

Stefani is a historic company based in Thiene (VI) and is part of the SCM Group. For decades, it has been the leading technological partner for furniture manufacturers requiring high-quality edging, with 80 registered patents and over 13,000 wood processing machines produced and marketed on all continents. The most innovative edging concepts proposed by Stefani are laser technology and the new Slim Line. After a research period of about four years in collaboration with a team of researchers from the Federico II University of Naples and prestigious European partners, Stefani has made another new development available: laser technology for the processing of furniture components. A panel-based piece of furniture can be produced without the use of edge glue, a material that has historically been a challenge for industrial furniture since the 1960s. It is a true generational change, as happened in music with the advent of mp3 or in communication with the advent of emails. Glue is no longer used, and its function is incredibly delegated to the materials themselves that compose the furniture, thanks to the new optical technology that "awakens" the dormant adhesive properties of these materials. A component or piece of furniture made without the use of glue approaches the appearance of one made by the most skilled craftsmanship, with the advantage of industrial production that can make these levels of perfection accessible to the local store and therefore to a higher number of consumers, contributing to the achievement of new levels of satisfaction and overall satisfaction. Laser edging technology is available on the range of Stefani Solution and Evolution edge banding machines.

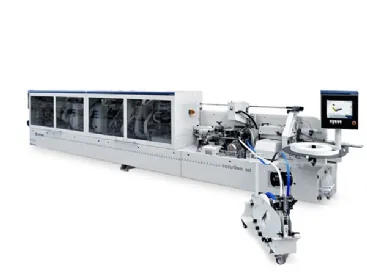

A patented technology and exclusive: Slim Line!

High quality finishing and low operating costs are guaranteed by edging technology Slim Line for the processing of furniture components. The innovative technological concept introduced by Slim Line immediately. The glue dosed on the edge, rather than on the panel, through a device in slot implies that the advantage of seeing eliminated the glue tank. The more homogeneous the surface of the board with respect to that of the panel allows to use less adhesive than traditional beading. With a wire thickness glue from 0.08 to 0.1 mm. length and height of the wire glue easily managed through the edge bander macchina.La Control Slim Line with polyurethane glue has the same cost range (0,028 pr a 500x500 mm panel thickness 18 mm) of border with thermo melt glue (0.025 for a panel equivalent) with many advantages in terms qualit.E about quality, Catas, the largest independent Italian institute for research and testing in the wood and furniture industry, certifies aloft technical and quality level of components for furniture made with process of edging Slim Line.