Also Abet Laminati among the Sicam exhibitors

Also Abet Laminati , a historic company founded in Bra in the 1950s specializing in the production of decorative laminates , was among the exhibitors of the twelfth edition of Sicam , the international exhibition of components, accessories and semi-finished products for the furniture industry, which was held from 12 to October 15, 2021 as usual at the Pordenone Fair .

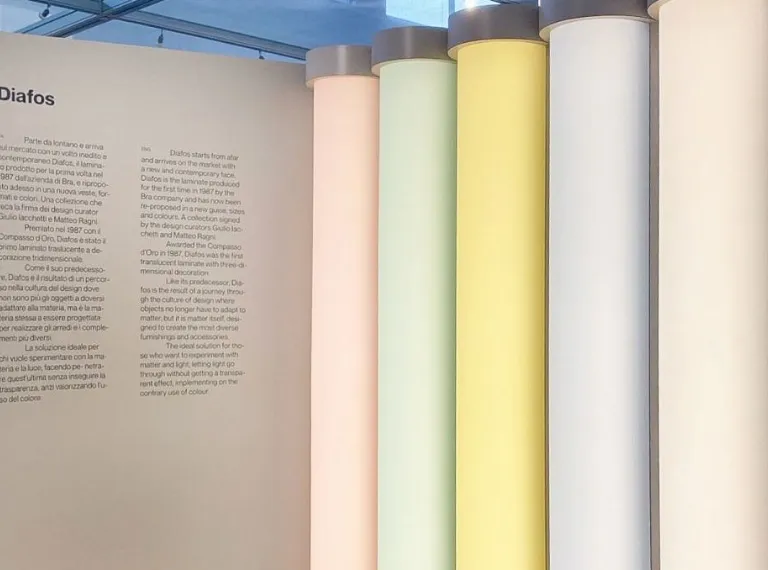

In the large space set up by the design curators Giulio Iacchetti and Matteo Ragni, the new Geo finish , the new solution for the Easy Meg facades and the Diafos laminate were previewed . But let's go into more detail.

The new products on display

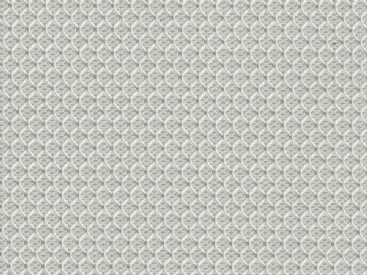

The Geo finish by Abet Laminati , characterized by a basic material and a slight ripple, inspired by natural elements and more precisely evokes the three-dimensional nature of the stone through a skilful alternation of rough grooves and smooth inlets.

Easy Meg is a ready-to-use system for the construction of external facades , it can be installed easily and quickly and requires minimal maintenance. You can choose between three different fastening systems : Closed Joint, Open Joint and Overlapping.

Diafos translucent laminate is not an absolute novelty. Let us explain: produced by Abet for the first time in 1987, it was awarded the Compasso d'Oro and undoubtedly one of the flagship of the company. Thanks to the contribution of Iacchetti and Ragni, however, it is now re-proposed in new formats and colors , more in line with current trends and also of great impact.

The other proposals by Abet Laminati at Sicam

In addition to the novelties, at Sicam 2021 Abet Laminati exhibited already existing products, which continue to be highly appreciated: Polaris and the Metalleido solutions . The first is a state- of-the-art opaque surface that is warm and soft to the touch, anti-fingerprint and characterized by high resistance to scratches and high temperatures.

The Metalleido brand , part of Abet since 2015, is instead identified by composite panels with aluminum or Nomex honeycomb cores, robust but light, elegant and versatile. Esacore and Monocore, for example, are respectively in aluminum and fiberglass and intended for the production of furniture components, kitchen tops, ceiling, wall and floor coverings. In all cases, the degree of customization is high .

We add that Abet Laminati recently completed the largest investment and development plan ever undertaken; part of this was the purchase of a new digital printer that arrived at the Bra site and is capable of producing up to 400 square meters of sheets per hour, with a maximum width of 1,860 mm.