Finishing Machinery

What would be the wooden furniture without finishing the highest quality standards? There are specialized oldest companies in its finishing lines, as Cefla Finishing Group, who attended allimportante stage Ligna Hanover 2015 (in dall11 scene to May 15), exposing its complete range of technologies, which testifies to the state of dellinnovazione art process and product.For about the increasingly high quality standards, the Cefla finishing Group finishing lines give the final product an aesthetic and performance continuous surplus value over time. They are insured efficiency and flexibility, essential today for productions in small batches, which require speed in format change, in the maintenance and sanitation. All this in the face of rapid dellinvestimento returns.

Finishing machines

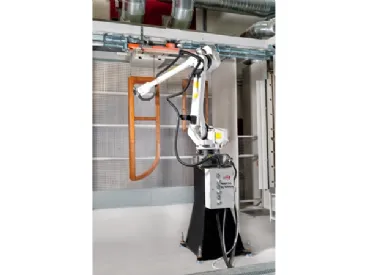

Not for nothing Cefla Finishing Group a world leader in the paint, decoration, digital printing of wood and its derivatives, designs and develops lines tailored and turnkey for the timber market. The experience gained over the years and the know-how gained in the field now make it an avant-garde group also in the glass industry, plastics, fiber cement, composite materials and metallo.Nella first image, the new spray Myth by Cefla Finishing presented at Ligna 2015 with two arms swinging with CFB transportation. Myth presents new, innovative patented plenum, with flow control daria in the car for maximum quality, low maintenance requirements and high paint transfer efficiency more. The shipping pieces SFBC system with carpet ensures the recovery of the paint, a long duration ambient tem, rapid replacement operations, absence of overspray in the bottom of the panel and perfect quality of the coating bordi.Nella second image, iBotic Cefla Finishing the ultimate expression of the panels spraying technology. It ensures finishes of the highest quality even with silhouettes and particular difficulties edges. The mechanics evolved allows for precise movements of the axes. The two arms are independent and can be moved individually or simultaneously: While one arm each other can work independently wipe and load with a different product. When loaded with the same product, they can work simultaneously helping to increase productivity. iBotic can spray in the oscillating mode for maximum flexibility combined with the robot mode. The CFB Carpet extended guarantees maximum delloverspray recovery.