Quality veneers

With over thirty years of experience and know-how, Il Tranciato has transformed over the years into one of the largest companies in the sector of veneer processing in various essences, capable of guaranteeing the client a constant quality of the final product. The manual dexterity and the expertise of the workers in the company is accompanied by technology: each stage of work is analyzed through a customized software system, always in the name of the excellence of the final result. 'last firmly pursued by the company's top management - for the choice of which the utmost attention is used, ensuring that certain qualitative criteria are always respected.The success of a company depends above all on the people who make it up: this is why it has always been of fundamental importance for the company management the investment in human resources, which are properly trained and updated over the years, in order to guarantee a considerable degree of specialization and, consequently, a high and constant quality level of veneers and veneers. a feature that makes Il Tranciato a prominent company undoubtedly resides in the continuous updating of machinery, including four-blade squaring machines, double-blade trimming and trimming machines, wire and glue splicers.

Wood veneers: characteristics and applications

But what exactly is a well-made wood veneer and what is it for? The veneer is made up of wooden sheets. The technique used for their processing is called "shearing". At the end of this process, very thin sheets or plates are obtained, ranging from 0.3 to 3 mm. It is from the horizontal cut of the trunks and based on their length that the veneers are obtained, which are used above all for the production of panels and other lamellar supports, used in the production of furnishings, furniture, furnishing accessories and other finished objects. There are numerous advantages deriving from this process, even if the veneers are often mistakenly considered less noble derivatives of wood, at a low price. However, in the face of affordable costs, these wooden sheets have a remarkable lightness and unparalleled manageability, a good resistance to attack by insects, such as woodworms and, at the same time, also a marked stability. After the shearing process, the wood passes to mechanical dryers for drying, a process that was once carried out in the open air. Drying and subsequent ironing are used to eliminate the nerve parts of the wood, so that the veneers, at the end of these operations, are smooth and polished.But where are the veneers applied? On supports of less noble materials such as MDF, chipboard, honeycomb, blockboard, to create components for the production of furniture or furnishings that have a look completely similar to solid wood, but with reduced costs and excellent quality. The veneer is the coupling phase between the support panels and the veneer slabs: it is generally performed with the use of hot presses and vinyl or urea glues. Working with high quality raw materials, all the veneers and veneers of Il Tranciato stand out for their innate excellence.

The processing of veneers

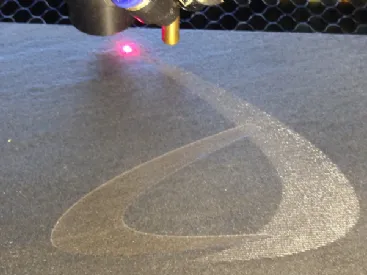

Il Tranciato, a company from Gaiarine, in the province of Treviso, expresses with its incomparable final product the passion for wood, a warm and living material. In fact, wood is a natural material and each log has unique properties in terms of hue, fiber and grain. But how is the log worked to obtain the best veneers? First of all, a careful selection of the logs is essential, to identify the ones that are best suited to the work to be carried out, taking into account their characteristics of grain and tonality. Although an accurate selection allows to obtain homogeneous batches of supplies, it is of fundamental importance to take into account the differences in color and small imperfections: in fact, it is true and proper typicality of wood that transform furniture and furnishings into truly elements. Once the material has been selected, the plants are subjected to the ironing process to remove the ripples, which would compromise the subsequent working phases. Then we proceed to the cut. To carry out the head cut, which is perpendicular to the fibers, trimming cutters with sharp blades are used, so as to oppose the resistance of the wood which, due to the perpendicular fibers, can quickly wear out the tools. For cutting in the grain direction, trimming cutters are used, which are equipped with very sharp blades since the resistance of the wood is lower, in this case. precision, simplifying subsequent processing. After the preparation of the veneer sheets in tailor-made packs, we proceed to the composition of the panels by combining the veneers in an optimal way to obtain the desired result. This is the most delicate phase, because the final result depends on it: it is carried out entirely by hand by personnel with extensive know-how. Once ready, the panels are sent to the spots that will join the sheets in the predefined order.This processing can be carried out in different ways: with wire machines, which join the sheets by means of a thin wire covered with hot melt glue, which is spread out. zig-zag keeps the sheets together, or with glue machines (in the case of Il Tranciato, it is direct glue) that spreads a thin thread of glue between the two sheets to be joined, eliminating any cutting imperfections and ensuring a painting perfect. All parts are joined with a thin pre-glued paper which, after pressing on a wood particle support, will be sanded off. This operation is called "veneer". The maintenance department, equipped with sharpening machines that ensures constantly regenerated tools, represents a further guarantee to obtain a practically perfect product of remarkable quality.