The advantages of laser cutting machines

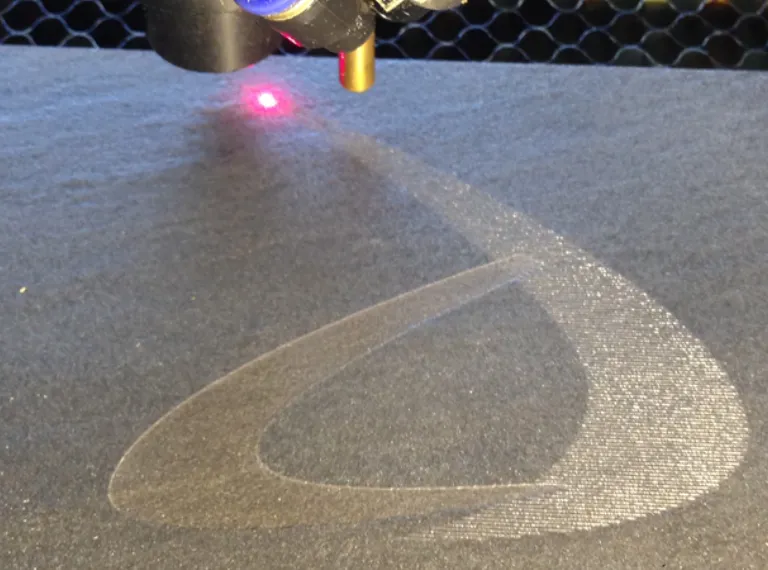

Sliced u200bu200bfrom the workings in the most diverse essences to those made u200bu200bwith laser cutting machines: the evolution of this the veneer , Historic Venetian company, which alongside the traditional core business of veneers that sees leaders since the Eighties, he added laser incision. Daltro hand incision laser ensures the edges much more clean cut and unestrema fine detail.

Thanks to laser cutting machinery The veneer produces not only on wood inlays, but develops altres customizations on different types of materials, such as leather, glass and aluminum. We do not also forget that the laser machines operate at high speed by increasing production levels and the range of proposals for clients. Combining the extensive know-how in the veneer to the new perspectives offered by the laser processing industry, The veneer inaugurates a new season for its already profitable activities.

High levels of customization

Thanks to laser cutting machines, The veneer able to easily and quickly perform the most complex of laser engraving operations, even on non-reflective metals, as well as on aluminum, glass, mirrors and ceramics. As we have already mentioned, we are guaranteed a high level of customization even for small items, such as handles and can insert company logos. And as for the cut? A laser machine capable of cutting the most varied materials, such as paper, cardboard, cloth, leather, leather, wood, plastic, methacrylate, stone, bamboo, polyurethane and plexiglass.

The laser process also safe Because it is unoperazione Contactless: the piece in fact should not be fixed in the course dopera and unlike traditional dincisione machines, laser printers have no moving parts that can harm the practitioner . Unottima evolution, then, for the veneer that in this way ready to accept new challenges by the numerous customers.