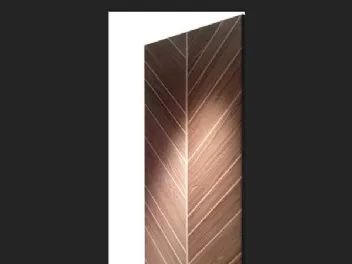

Alpi, a company specializing in the production of wooden surfaces, has created the new French Palette and Wavy Fir collections.

Alpi inaugurates spring 2021 by presenting the new collection of wooden surfaces French Palette, created in collaboration with Piero Lissoni.

A Space&Interiors, Fantoni has introduced its new fonassorbenti systems, which are real acoustic solutions, emphasizing especially versatility and ...

Teknowood the innovative multimedia panel intended for the contract market, is produced by Busnelli International, a leading company in the supply of ...

Two panels complement each other and have unique performance qualities of their kind: it is MAXXIGLOSS and MAXXIMATT of Opera3B

Buyers and designers looking for the latest generation of contemporary panels can turn to Saib, which belongs to the group of major manufacturers

Buyers and design studios can turn to for their applications to Florian Group manufacturer of semi-finished floors, furniture, windows, stairs

Purchasing offices and designers will remain undoubtedly affected by Concreo, the innovative panel capable of revolutionizing the ambient tem mode of ...

design studios and major brand buyers will often turn to Cleaf for the innovative potential of its furniture panels

Caimi Brevetti proposes purchasing offices a wide range of patented products to distinguish the sound-absorbing panels

The initiatives and technologies for the sustainability of MDF panels flourish: we illustrate them in this article, which will arouse the interest of ...

Slalom is a company focused on development and research in the acoustic field, both in terms of know-how and design: its acoustic panels are known

Designer and responsible purchasing departments often choose decorative panels bi or three-dimensional, since they represent a new type of decoration ...

In the following article, we will illustrate the characteristics and properties of the melamine panel, revealing why so used in kitchens

SM'art produces melamine panels composed of high quality raw materials which ensure innovative technical and aesthetic results to professionals in ...

The Mauro Saviola Group, which is part of Saviola Holding, offers purchasing offices and design studios a green design for panels

The Group Friars in terms of decorative offers maximum support for its customers, offering an unrivaled range breadth and variety

Bencore designs and produces honeycomb structured thermoplastic composite panels, offering a wide range to procurement offices and designers.

Panels and finishes, raw materials and semi-finished products: by choosing a supplier like Fantoni, purchasing offices and designers of major ...

Design and manufacture of innovative panels for the furniture sector: this is one of the objectives of Breda, at the forefront of the sector

Bonomi Shoes offers a wide assortment of fruit panels of an intense activity of R&S and thus highly innovative

Buyers and purchasing managers require raw and faced chipboard panels quality and prefer cutting-edge sector, as Saib

With its decorative surfaces and its wide range of panels and finishes, Cleaf satisfies the most stringent needs of purchasing offices and designers ...

Bellotti offers buyers in the furniture industry panels assembled with innovative and technological materials with acoustic and thermal insulation ...

Alpine offers a new line of multilaminar wood panels processed as if they were tissue: it is a wide range ready for the purchasing offices of major ...

The Slalom absorbers are essential in certain environments: they know it project managers and designers